-

Guide wheel/EDM Guide Wheel/Wire Cut Guide wheel

1.The functions of guide wheel in high speed wire cut machine: HS-WEDM guide wheel is mainly used to provide stable transmission and orientation for molybdenum wire. The quality of guide wheel directly impact the precision and surface finish of the workpiece.

2. The technical parameters of EDM guide wheel in high speed machining:

V-shaped groove runout≤0.04MM,

Radial Jump≤0.004MM,

Axial Jump≤0.004MM.3.The materials of wire cut guide wheel in FS-WEDM: steel guide wheel, sapphire guide wheel, ceramic guide wheel.

4. The shapes of guide wheel in high speed wire EDM: uniaxial guide wheel, biaxial guide wheel.

-

Guide Wheel Pulley Assembly/Brass Seat Pulley Assembly/EDM Pulley Assembly

1. The functions of guide wheel pulley assembly in high speed wire cut machine: HS-WEDM guide wheel pulley assembly is mainly used to provide stable transmission and orientation for molybdenum wire.

2.The materials of wire cut guide wheel pulley assembly in FS-WEDM: brass seat for guide wheel pulley assembly, plexiglass/organic glass/plastic seat guide assembly of WEDM wire cut parts.

3.The shapes of guide wheel pulley assembly in high speed wire EDM: uniaxial guide pulley assembly, biaxial guide pulley assembly.

4.High speed wire cut guide wheel pulley assembly is made up of guide wheel, bearings, brass seat, nuts and end caps.

-

Power Feed Contact/Carbide Power Feed Contact/Wire Cut Carbide

1.The functions of power feed contact in High Speed Wire Cut EDM: power feed contact of HS-WEDM is mainly used to produce a steady supply of electricity for Molybdenum wire.

2.The features of carbide power feed contact in high speed wire cut: high hardness, large density, smooth surface, and rounded transition.

3. The materials of wire cut carbide in high speed CNC EDM wire cut machine: cemented carbide

-

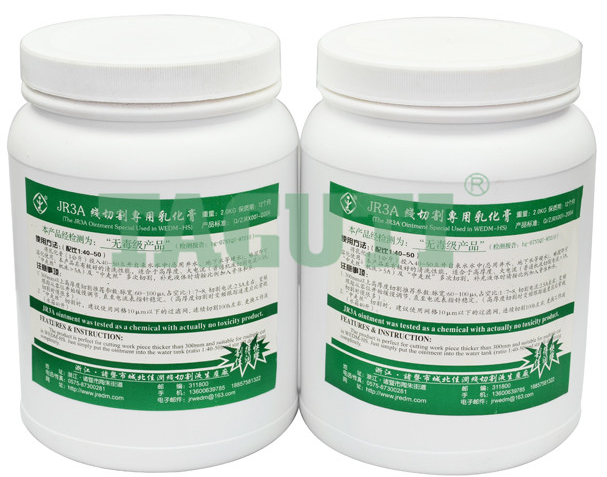

JR-3A WEDM concentrated ointment

Concentration Solution Put the ointment into running water with a ratio 1:40-50 (ointment:water) and stir until mix the ointment into water thoroughly. Ingredients: Green product for the environment Using range: Specialized for all types of Wire-cutting Electric Discharge Machine ( WEDM—HS ). It can be also used as cooling liquid for grinder, lathe, miller and other kinds of black metal’s machining processes. Features: The product is based on WEDM solid soap. It inherits the advandage of solid soap like high oil:water ratio, convenient shipping, and dissolves as quickly as oil. 1. Uniform and white finish surface almost without stripe. 2. Improve machining efficiency 30% more and surface finish degree one grade more. 3. Improve machining process indexes especially when cutting workpiece thicker than 300mm. 4. Workpiece is easy to take off and clean. 5. Specially suitable for multiple-cut of WEDM-HS. Expire Date 12 months Package 2KG Special Plastic Bottle. 18KG/BOX,(2*9 bottles) Attention Please do not mix other emulsified oil into the tank, otherwise, will decrease the performance .