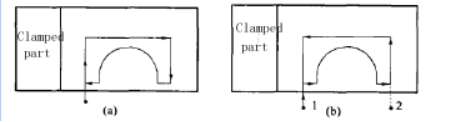

Figure 6 – 5

(a) False (b) Correct

(2) Use closed cutting with a threaded hole. When punching parts such as punches, it is customary not to consider punching through the holes, but to cut them through a lengthy induction program from outside the material boundary. This operation is very convenient, but is easily affected by the internal stress of the material. In some occasions where the precision of machining is required to be high, the threading holes should be pre-processed and closed cutting is adopted so that the waste materials removed from the workpiece materials are still connected together, which contributes to the fixed position of the workpiece and the improvement of machining accuracy.

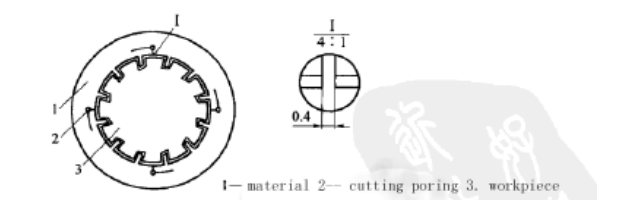

(3) Use multi-start point cutting process. For large parts with strict requirements for machining accuracy, such as medium and large punches, even if closed machining is used, there will be a slit (the discharge gap with a slit width of 2 times the diameter of the electrode wire is shown in the manual (3 – IO) ) The distortion occurs. In order to reduce the impact of this deformation, a multi-start cutting process using molybdenum wire or brass wire can be adopted so that the support of each site is cut off. The work pieces shown in Fig. 6-6 are based on the 4-point cutting T-art. The 4 symmetrical bearing points are 0.4 mm wide. This process method can diminish the deformation of the workpiece.

(2) Use closed cutting with a threaded hole. When punching parts such as punches, it is customary not to consider punching through the holes, but to cut them through a lengthy induction program from outside the material boundary. This operation is very convenient, but is easily affected by the internal stress of the material. In some occasions where the precision of machining is required to be high, the threading holes should be pre-processed and closed cutting is adopted so that the waste materials removed from the workpiece materials are still connected together, which contributes to the fixed position of the workpiece and the improvement of machining accuracy.

(3) Use multi-start point cutting process. For large parts with strict requirements for machining accuracy, such as medium and large punches, even if closed machining is used, there will be a slit (the discharge gap with a slit width of 2 times the diameter of the electrode wire is shown in the manual (3 – IO) ) The distortion occurs. In order to reduce the impact of this deformation, a multi-start cutting process using molybdenum wire or brass wire can be adopted so that the support of each site is cut off. The work pieces shown in Fig. 6-6 are based on the 4-point cutting T-art. The 4 symmetrical bearing points are 0.4 mm wide. This process method can diminish the deformation of the workpiece.

(4) Take effective measures to ensure smooth running of the wire drawing system. The tensioning mechanism is applied to the wire (molybdenum wire or brass wire) running system of the low speed wire cutting machine, which can ensure the smooth movement of the wire and the constant tension. However, the electrode wire(brass wire not molybdenum rutting wire) cut by the high-speed wire cutting is a high-speed reciprocating movement, which easily causes jitter and looseness of the electrode wire. Therefore it requires:

①After the heart has been processed for a period of time, it must be tight;

②Wire barrel, guides, Conductor blocks should be inspected regularly and any damage should be promptly replaced.

③Periodically correct the perpendicularity of the electrode wire to the work surface;

④ Always correct the programming compensation in real-time based on the size of the wire (molybdenum rutting wire or brass wire) after the wire loss.

(where to buy molybdenum wire? and need molybdenum wire price? Please visit www.edm-taguti.com, China’s biggest molybdenum wire china manufacturer and exports self developed and patented “cold-drawing” molybdenum cutting wire.